The Duravant family of operating companies serve the food processing, packaging and material handling segments.

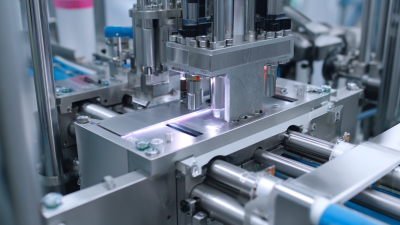

Revolutionizing Production Efficiency: Understanding the Future of Filling Machines in Manufacturing

In the ever-evolving landscape of manufacturing, production efficiency remains at the forefront of industry innovation. One key player in this transformation is the filling machine, a vital component in various sectors from food and beverage to pharmaceuticals. As manufacturers strive to streamline operations and reduce costs, understanding the future of filling machines becomes essential. This article delves into the technological advancements, automation trends, and smart capabilities that are set to redefine how filling machines function within production lines. By examining the latest developments and the potential for increased efficiency, we aim to guide manufacturers in adapting to this changing environment. Join us as we explore strategies to optimize filling machine performance, ultimately revolutionizing production processes and setting new standards for excellence in manufacturing.

The Role of Advanced Automation in Modern Filling Machines

The integration of advanced automation into modern filling machines is reshaping the landscape of manufacturing efficiency. According to a report by MarketsandMarkets, the global liquid filling machine market is projected to reach USD 8.3 billion by 2025, with a significant portion of growth driven by automation technologies. These machines not only enhance precision but also drastically reduce operational costs and labor requirements, allowing manufacturers to maintain competitive edges in increasingly crowded markets.

Furthermore, the adoption of Industry 4.0 principles has spurred the development of smart filling machines equipped with IoT capabilities. These systems enable real-time monitoring and data analysis, leading to better decision-making and minimizing downtime. A publication by Research and Markets suggests that the efficiency of automated filling systems can increase by up to 30% compared to traditional methods. As manufacturers invest in such technology, they are not only streamlining their operations but also positioning themselves for a more resilient future in the face of evolving industry demands.

Innovations in Filling Machine Technology and Their Impact on Production

The future of filling machines in manufacturing is being shaped by several innovative technologies that enhance production efficiency. One of the most significant advancements is the integration of automation and robotics, which streamline the filling process. Automated systems reduce human error, increase speed, and ensure consistent quality, allowing manufacturers to meet growing demand with minimal downtime.

Advanced sensors and smart monitoring systems further elevate performance by providing real-time data analytics that optimize operations and proactively address potential issues.

Additionally, the development of sustainable materials and eco-friendly designs is transforming filling machine technology. New filling machines are being equipped with systems that minimize waste and utilize biodegradable materials, aligning production practices with environmental responsibility.

These innovations not only contribute to greater efficiency and cost savings but also appeal to environmentally conscious consumers. As manufacturers embrace these technologies, the future of filling machines promises to revolutionize production processes, driving both profitability and sustainability in the manufacturing sector.

Understanding the Benefits of High-Speed Filling Systems

High-speed filling systems are becoming a cornerstone in the manufacturing industry, primarily due to their ability to significantly enhance production efficiency. According to a recent report by Market Research Future, the global filling machines market is projected to reach USD 6.9 billion by 2024, growing at a CAGR of 5.8%. This growth is largely driven by the increasing demand for rapid packaging solutions across sectors such as food and beverage, pharmaceuticals, and cosmetics. Implementing high-speed filling systems can reduce downtime and increase output, making them invaluable for companies aiming to stay competitive.

Tips: When considering the integration of a high-speed filling system, evaluate the compatibility with your existing production lines to ensure seamless operation. Moreover, investing in state-of-the-art technology not only boosts efficiency but also enhances accuracy, reducing product wastage and lowering costs.

The benefits extend beyond mere speed. High-speed filling systems often come equipped with advanced monitoring features that ensure consistent quality control. A study by Technavio highlights that companies can achieve up to a 25% increase in productivity through automation and high-speed technologies. Manufacturer adaptability and scalability are crucial in today’s market, making these systems not just a trend, but a necessity for future-focused operations.

Tips: Regularly train your workforce on new technologies and systems to maximize the effectiveness of high-speed machines and maintain high standards of safety and performance in your manufacturing process.

Revolutionizing Production Efficiency: Understanding the Future of Filling Machines in Manufacturing

| Filling Machine Type | Speed (Bottles per Minute) | Accuracy (%) | Technology Used | Applications |

|---|---|---|---|---|

| Rotary Filling Machine | 200 | 99.5 | Pneumatic | Beverages, Chemicals |

| Overflow Filling Machine | 150 | 98.8 | Gravity | Food Products, Cosmetics |

| Piston Filling Machine | 100 | 99.0 | Servo Driven | Viscous Liquids, Creams |

| Volumetric Filling Machine | 120 | 99.2 | Electromagnetic | Pet Food, Pharmaceuticals |

| Auger Filling Machine | 80 | 98.5 | Positive Displacement | Powdered Products, Granules |

Adapting to Industry 4.0: The Future of Smart Filling Solutions

The advent of Industry 4.0 has ushered in a new era for manufacturing, dramatically reshaping traditional practices and operational frameworks. Smart filling solutions are at the forefront of this transformation, integrating advanced technologies like IoT, artificial intelligence, and machine learning to enhance production efficiency. These innovations enable real-time monitoring, predictive maintenance, and data analytics, allowing manufacturers to streamline their processes and reduce downtime.

In a landscape driven by data, filling machines equipped with smart technology can adapt to fluctuating market demands with unprecedented agility. By leveraging connectivity and automation, manufacturers can achieve greater flexibility in production runs, minimizing waste and optimizing resource allocation. Such adaptability not only meets consumer expectations for customization and speed but also aligns with sustainability goals, reducing the environmental impact of manufacturing operations. As industries continue to evolve, embracing smart filling solutions will be crucial for staying competitive in an increasingly dynamic marketplace.

Revolutionizing Production Efficiency: Filling Machines in Manufacturing

This chart illustrates the production efficiency percentages of different types of filling machines used in the manufacturing sector, highlighting the advantages of integrating smart filling solutions in the context of Industry 4.0.

Sustainability and Efficiency: Eco-Friendly Practices in Filling Processes

As the manufacturing sector evolves, sustainability has become a pivotal focus, particularly in filling processes. Reports from the International Journal of Life Cycle Assessment indicate that optimizing filling machines can reduce operational waste by up to 30%, significantly decreasing the environmental impact associated with traditional methods. These eco-friendly practices not only cater to regulatory compliance but also enhance corporate social responsibility, appealing to increasingly eco-conscious consumers.

Related Posts

-

The Future of Advanced Filling Machine Technology in Modern Manufacturing

-

Troubleshooting Common Issues with Different Types of Filling Machines

-

Advantages of Embracing Automated Packaging Solutions for Global Supply Chains

-

The Evolution of Industrial Filling Machines in Global Supply Chains

-

5 Essential Tips for Choosing the Right Filling Machine to Boost Production Efficiency by 40%

-

Elevating Global Standards: How China's Best Industrial Packaging Machines Redefine Quality and Trust