The Duravant family of operating companies serve the food processing, packaging and material handling segments.

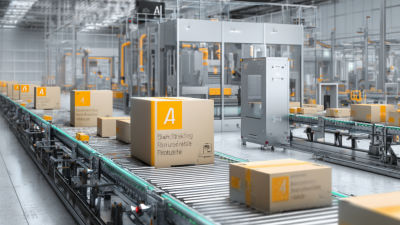

Ultimate Guide to Mastering Automated Packaging Strategies for Your Business

In today's fast-paced business environment, implementing effective automated packaging strategies is not just an option; it has become a necessity for companies looking to enhance efficiency and reduce costs. This ultimate guide is designed to empower you with the knowledge and tools needed to master automated packaging, streamlining your operations and maximizing productivity. From understanding the latest technologies to evaluating your current processes, we will walk you through the critical steps to transform your packaging practices. As we delve into various automated packaging solutions, you'll learn how to identify the right strategies for your business needs, ensuring that you stay competitive in a rapidly evolving market. By the end of this guide, you'll be equipped with actionable insights that will not only improve your packaging operations but also contribute to overall business success.

Identifying Common Issues in Automated Packaging Systems

Automated packaging systems have revolutionized the way businesses operate, yet they are not without their challenges. Identifying common issues in these systems is vital to ensure efficiency, reduce waste, and maintain product integrity. One prevalent problem is equipment malfunction. Regular maintenance and timely repairs are essential to prevent costly downtime and ensure that the packaging process runs smoothly.

Another significant issue arises from compatibility problems between packaging materials and machines. Incompatible materials can lead to jams, improper seals, or product damage. Businesses must invest in proper training and continuous assessment of their packaging lines to select appropriate materials that work seamlessly with their machines. Additionally, monitoring and adjusting machine settings for different products can mitigate these types of problems, leading to more consistent output.

Finally, employee training plays a crucial role in the success of automated packaging systems. Well-trained personnel can promptly identify and resolve issues, minimizing the impact on production. Continuous education on the latest technologies and troubleshooting techniques can empower staff to maintain optimal efficiency and adapt to evolving production requirements. By addressing these common issues head-on, businesses can enhance their automated packaging strategies and thrive in a competitive market.

Automated Packaging System Common Issues

Understanding the Impact of Poor Packaging Practices on Business Efficiency

The significance of effective packaging in business operations cannot be overstated. Poor packaging practices can lead to a cascade of inefficiencies that ultimately impact a company's bottom line. When products are inadequately packaged, they are more susceptible to damage during transit, leading to increased return rates and customer dissatisfaction. This not only adds to the operational costs but can also tarnish a brand's reputation, making customers hesitant to repeat purchases or recommend the product to others.

Moreover, inefficient packaging often results in wasted space in shipping containers, which can escalate freight costs significantly. If businesses do not optimize their packaging, they may end up paying for unused or unnecessary space, thereby diminishing overall profitability. Transitioning to automated packaging solutions can alleviate these pain points, ensuring products are securely packed while maximizing space efficiency. By investing in smart packaging strategies, companies can streamline their logistics, enhance customer satisfaction, and promote sustainable practices—all of which contribute to better business efficiency.

Strategies to Overcome Packaging Automation Hurdles

Automated packaging can significantly enhance operational efficiency, but many businesses encounter hurdles that hinder effective implementation. One common challenge is the resistance to change within an organization. Employees may feel uncertain about adopting new technologies, fearing job loss or skill obsolescence. To tackle this, businesses should prioritize comprehensive training programs that empower staff, highlighting the benefits of automation not just for the company but for their roles as well. Involving employees early in the decision-making process can also improve buy-in and alleviate concerns.

Another significant obstacle is the integration of automated systems with existing workflows. Companies often find that legacy equipment and software do not seamlessly connect with new automation technologies. To overcome this, conducting a thorough assessment of current systems is crucial. Businesses should invest in flexible automation solutions that can adapt to existing processes or plan for necessary upgrades to facilitate smooth integration. By addressing these challenges head-on, companies can successfully harness the power of automated packaging, streamlining their operations and reducing costs in the long run.

Evaluating Technology Solutions for Improved Packaging Processes

In today's competitive market, evaluating technology solutions for improved packaging processes is essential for businesses aiming to optimize efficiency and sustainability. Recent studies emphasize the importance of integrating advanced technologies such as deep learning (DL) and machine learning (ML) in supply chain management. For instance, these technologies can enhance supplier selection and inventory control, ultimately leading to more streamlined packaging operations.

Moreover, the environmental impact of packaging materials is under increasing scrutiny. Research indicates that shifting from traditional polyamide multilayer films to more recyclable alternatives can significantly reduce the carbon footprint. A life cycle assessment of plastic food packaging reveals its potential in minimizing food waste while preserving marine ecosystem services. This highlights the urgent need for companies to adopt innovative packaging solutions that align with both economic and environmental sustainability goals.

By leveraging comprehensive assessment tools, businesses can not only improve their packaging processes but also contribute to a circular economy. For example, implementing material flow analysis can provide insights into the circularity of plastic packaging, facilitating better resource management. This proactive approach can ultimately result in cost savings and heightened customer loyalty in an era increasingly focused on sustainability.

Best Practices for Maintaining Quality in Automated Packaging

Ensuring quality in automated packaging is crucial for any business looking to streamline its operations while maintaining high standards. To achieve this, regular maintenance of machinery is essential. Implement a schedule for routine inspections and servicing to catch any potential issues before they escalate. This proactive approach not only saves time but also ensures that your equipment performs optimally, preserving the integrity of your packaging process.

Another key aspect is to invest in quality control measures. Utilize sensors and cameras to monitor package integrity throughout the automated process. By incorporating real-time feedback systems, you can quickly identify defects and correct them, ensuring that each product meets your high-quality standards.

Lastly, training your staff on the automated systems is vital for maintaining quality. Empower your team with the knowledge and skills they need to troubleshoot and adjust packaging machines as necessary. Regular training sessions can help keep everyone updated on best practices and new technologies, ultimately leading to improved efficiency and product quality. By following these strategies, businesses can master automated packaging while upholding quality across their operations.

Ultimate Guide to Mastering Automated Packaging Strategies for Your Business - Best Practices for Maintaining Quality in Automated Packaging

| Strategy | Description | Benefits | Challenges | Best Practices |

|---|---|---|---|---|

| Automated Sealing | Use machines to seal packages quickly and efficiently. | Increased speed and reduced labor costs. | Potential for seal failures if not maintained properly. | Regular maintenance and employee training on machines. |

| Robotic Packing | Utilizing robots to pack products into shipping boxes. | Consistency and precision in packing. | High initial investment and maintenance costs. | Conduct cost-benefit analysis before implementing. |

| Smart Packaging | Using technology to track and monitor package conditions. | Enhanced product quality and customer satisfaction. | Requires integration with existing systems. | Implement phased rollouts to minimize disruption. |

| Reusable Packaging | Designing packages that can be reused multiple times. | Reduces waste and lowers overall costs. | May require changes in logistics processes. | Collaborate with suppliers to establish return systems. |

| Quality Control Automation | Automating the inspection of products for defects. | Improved accuracy and reduced human error. | Initial setup can be complex and costly. | Invest in training for operators on new systems. |

Related Posts

-

Advantages of Embracing Automated Packaging Solutions for Global Supply Chains

-

Top Automated Packaging Solutions That Transform Your Supply Chain Efficiency

-

Discover Superior Automated Packaging Solutions from China's Leading Manufacturers for Global Partnerships

-

Revolutionizing Packaging Systems: Trends to Watch in 2025 and How to Adapt Your Strategy

-

7 Innovative Ways Automated Packaging Transforms Your Business Efficiency

-

7 Reasons Why Best Automated Packaging Solutions Will Transform Your Business in 2023